Storage & Transfer

Lubricant treatment and all related handlings to keep it clean and dry begins at the point of entry at the plant. There is likely more than one action before oil is transferred into a machine. And even if that is the case within the trajectory, when the proper storage and transfer devices are lacking, we haven’t done anything right. First, we should understand that upon delivery at the plant, new oil does not mean that it is clean! New oil needs pre-filtration, which can be done in a lubrication room or lube room.

Lube rooms should be a standard utility in contemporary business activities. It is more than a room where lubricants are stored. Here lubricants are handled with care and are only accessible to trained personnel. The environment must be free of dirt and moisture and kept at a constant temperature.

The central function of the lube room is to store and filtrate new oil before it is used. Storage can be in clean, undamaged drums placed on drum racks and filtered with a filter cart or drum topper. Another option is the LT-LMS storage with a built-in filter unit and also equipped with a desiccant breather.

A lube room is where a company can create and implement a culture of accurate and effective lubricant handling.

The luberoom attendant makes sure he or she keeps records of the inventory and sees to it that devices are appropriately used to prevent cross contamination.

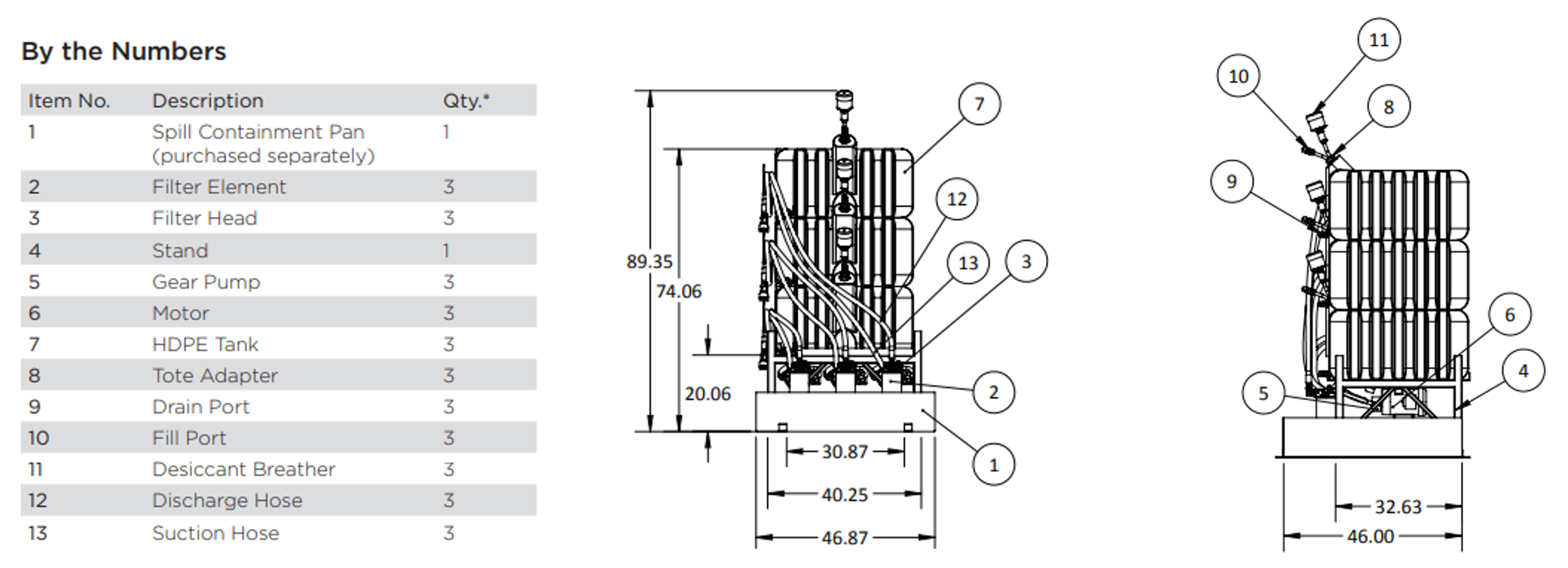

LT-LMS Bulk Storage

Simple, stackable and easy storage meets solid contamination control practices in a unique design with the LT-Series Lubricant Management System (LT-LMS). Dedicated filtration per container ensures no cross-contamination of fluids, while disposable desiccant breathers prevent dirt and water ingression. These all-in-one systems are completely customizable− offering various flow rates, container sizes, quick connect fittings, steel and HDPE tanks, and accessories. And even better yet, these systems are easy to use and install.

Oil Transfer Containers

Oil Transfer Containers provide the first best practice solution to keep oil clean and dry during oil transfer. With non-desiccant and desiccant breather options available, as well as quick connects for clean filling, these transfer containers isolate oil from the environment providing the ultimate in best practice contamination control.

Key benefits

- Isolates and protects oil to meet best practice standards with breathers and ISO B quick connects

- Provides variable flow control with trigger mechanism

- Square containers store 27% more volume per square foot than round containers

- Prevents cross contamination and provides easy lubricant identification with 11-colorcoding options and tagging system

- Minimizes inventory management with modular, interchangeable spouts, collar rings, and pump caps as the only color-coded components