Filtration Solutions

Contamination is widely recognized as the leading cause of failure in rotating and reciprocating equipment. In fact, as much as 80% of machine wear can be related to lubricant contamination. The cleanliness of lubricants is crucial at any time in a working machine, where friction is unwanted and smooth functioning is the goal.

Maintaining lubricant purity in these working machines can be achieved through the cooperative efforts of breathers, filter units, and appropriate lubricant storage. This is a solid and potent combination, which not only protects against wear and tear but also guarantees the durability and effectiveness of machinery parts and components.

Portable Filtration

Portable filtration units are the perfect instruments when it comes to cleaning up polluted systems, commissioning new equipment, or routinely decontaminating systems with insufficient on-board filtration to achieve desired levels of cleanliness. Our filtration systems are designed for simple maneuverability throughout plant floors with their robust frames, industrial-duty pneumatic tires, and high-quality components. They are small but powerful tools that can clean up hydraulic fluids wherever they are needed. Due to their design and maneuverability, they are easy and convenient to operate on-the-spot.

Filter Cart

Applications

Decontaminating systems

Flushing new or repaired systems

Dispensing new oil

Pre-filtering new oil

Evacuating used oil

Reservoir top-offs

Flushing systems

Collecting oil samples for analysis

Ideal for use on small to medium-sized reservoirs with low flow rates. Compatible with mineral-based industrial fluids and offer an affordable way to maintain fluid cleanliness in numerous applications using the same lubricant.

Customizable to your preference in voltage/cycle/phase, RPMS and available in air driven version.

Intended Use

To be used for offline, secondary filtration and not inline filtration

In general industrial environments, both indoors and outdoors (IP rating of 54)

For filtering mineral-based industrial oils and most synthetic oils with a maximum operating viscosity range of ISO 680 at 100°F/38°C (3,000 ssu/648cSt) within ambient temperature ranges of -15°F to 150°F (-26°C to 66°C)

Placed at the same level or below the equipment being filtered and within reach of the recommended standard 12 foot hoses

This system should be stored and used on a level surface, right side up, in a low-traffic area, and connected to the appropriate power source

Drum Filter cart

Applications:

- Decontaminating systems

- Flushing new or repaired systems

- Dispensing oil

- Pre-filtering new oil

- Evacuating used oil

- Topping off reservoirs

- Collecting oil samples for analysis

This cart is ideal for pre-cleaning, protecting, and transferring oil from a conveniently attachable, secured drum. A drum adapter kit with a desiccant breather is included for complete contamination control.

For filtering mineral-based industrial oils and most synthetic oils with a maximum operating viscosity range of ISO VG 680 (3000ssu/ 648cSt) at 100°F/38°C within ambient temperature ranges of -15°F to 150°F (-26°C to 66°C).

What is Standard:

- Automatic pressure relief valve

- Dual-stage filtration

- 12′ hose assemblies with various quick connect options

- Rugged, powder-coated dolly with plastic removable drip pan

- Adjustable, heavy-duty straps with spring-loaded clips to secure drum

- Remote-mounted power switch

- Casters for easy mobility

- Mating color-coded drum adapter kit for easy connection

Drum Topper

Applications

- Decontaminating systems

- Flushing new or repaired systems

- Dispensing new oil

- Pre-filtering new oil

- Evacuating used oil

- Topping off reservoirs

- Collecting oil samples for analysis

Compact, portable and customized for your application, the drum topper is an option you can carry wherever you need to go. Our drum topper provides many uses, including:

- Filtering new oil directly from the drum

- Allowing you to fill small totes

- Acting as an offline filter for critical equipment

Customizable to your preference in voltage/cycle/phase, RPMS and available in air driven version.

Intended Use

To be used for offline, secondary filtration and not inline filtration

In general industrial environments, both indoors and outdoors (IP rating of 54)

For filtering mineral-based industrial oils and most synthetic oils with a maximum operating viscosity range of ISO 460 at 100°F/38°C within ambient temperature ranges of -8°F to 104°F (-22°C to 40°C)

Placed at the same level or below the equipment being filtered and within reach of the recommended standard 6 foot hoses

This system should be stored and used on a level surface, right side up, in a low-traffic area, and connected to the appropriate power source

TC Series T-Stand

Applications

- Decontaminating systems

- Flushing new or repaired systems

- Dispensing new oil

- Pre-filtering new oil

- Evacuating used oil

- Topping-off reservoirs

- Collecting oil samples for analysis

These robust carts are built to last for many years and can remove debris and/or free water from any kind of oil, including highly viscous gear oils.

Large reservoirs with high flow rates are the perfect fit for the TC Series filter carts. The TC Series carts can remove everything from big particles and debris, sludge, varnish, and water contamination. The canisters may handle different filter types, including microfiberglass drop-in filters, depth filters, and bag filters.

Customizable to your preference in voltage/cycle/phase, RPMS.

Intended Use

To be used for offline, secondary filtration and not inline filtration.

In general industrial environments, both indoors and outdoors.

For filtering mineral-based industrial oils and most synthetic oils with a maximum operating viscosity range of 32-648cSt (150-3000ssu) within ambient temperature ranges of -25°F to 104°F (-32°C to 40°C).

Placed at the same level or below the equipment being filtered and within reach of the recommended standard 12-foot hoses.

This system should be stored and used on a level surface, right side up, in a low-traffic area, and connected to the appropriate power source.

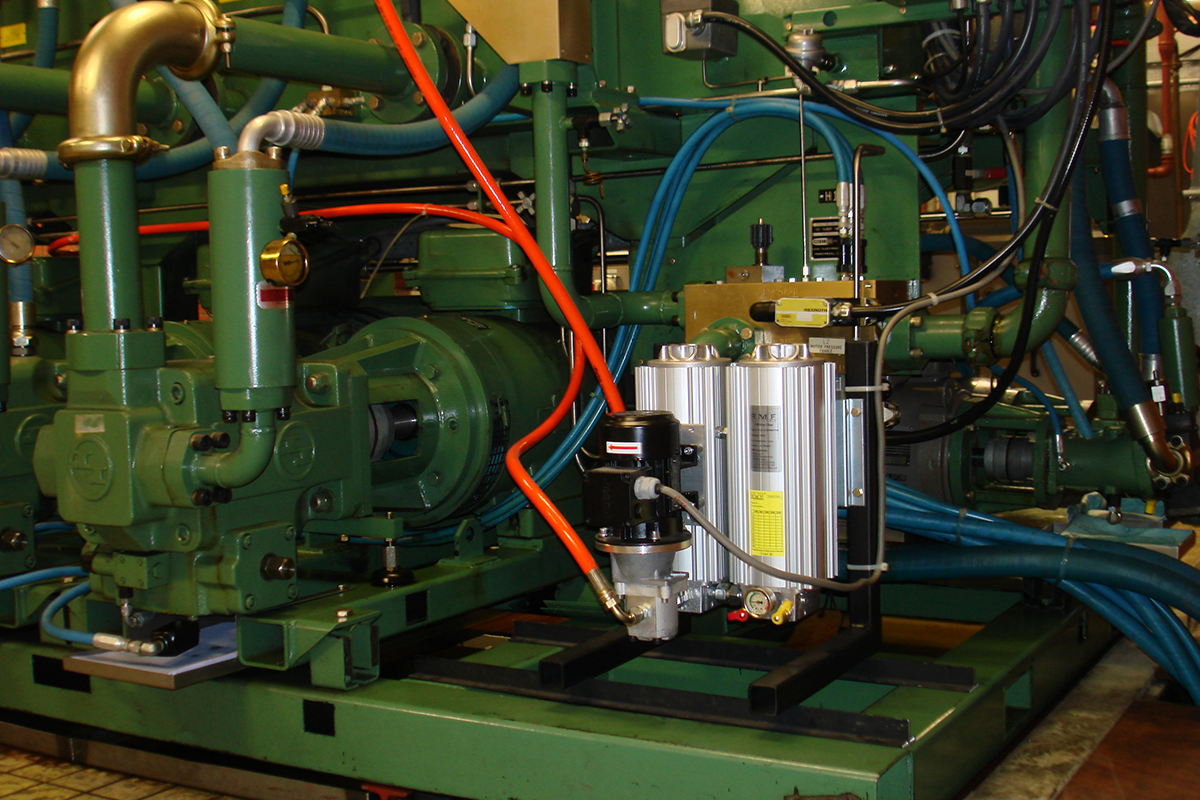

Dedicated Filtration

Permanent and continuous filtration providing longer-term optimization of fluid cleanliness for equipment that is difficult to access or expensive to maintain. Although contamination is frequently disregarded as a contributing factor to early machinery failure and shorter lubricant life, the best investment a business can make is keeping oil clean. With the rising cost of oil, the growing need to reduce consumption and waste, and the requirement to extend equipment life, there is a justified argument for pre-filtration of oil from the point of entry into a facility to the point of exit. Compared to the advantages of portable systems, permanent solutions offer several benefits including better average fluid cleanliness and far fewer man-hours.

By-pass Units

The Bypass Units are especially designed for mobile application in hydraulic and/or transmission systems. It comes equipped with an integrated pressure compensated flow control valve. This valve bleeds oil from the main hydraulic system, passes this through the filter after which it is returned to the hydraulic reservoir. The amount of oil extracted from the main system at any time is insignificant ensuring that it will not affect the working of the main system.

By-pass units are commonly used for keeping hydraulic and transmission systems clean on:

- excavators

- wheel loaders

- forestry machines

- asphalt machines

- concrete pumps

- aviation ground support equipment

- agricultural machines

Off-Line Units

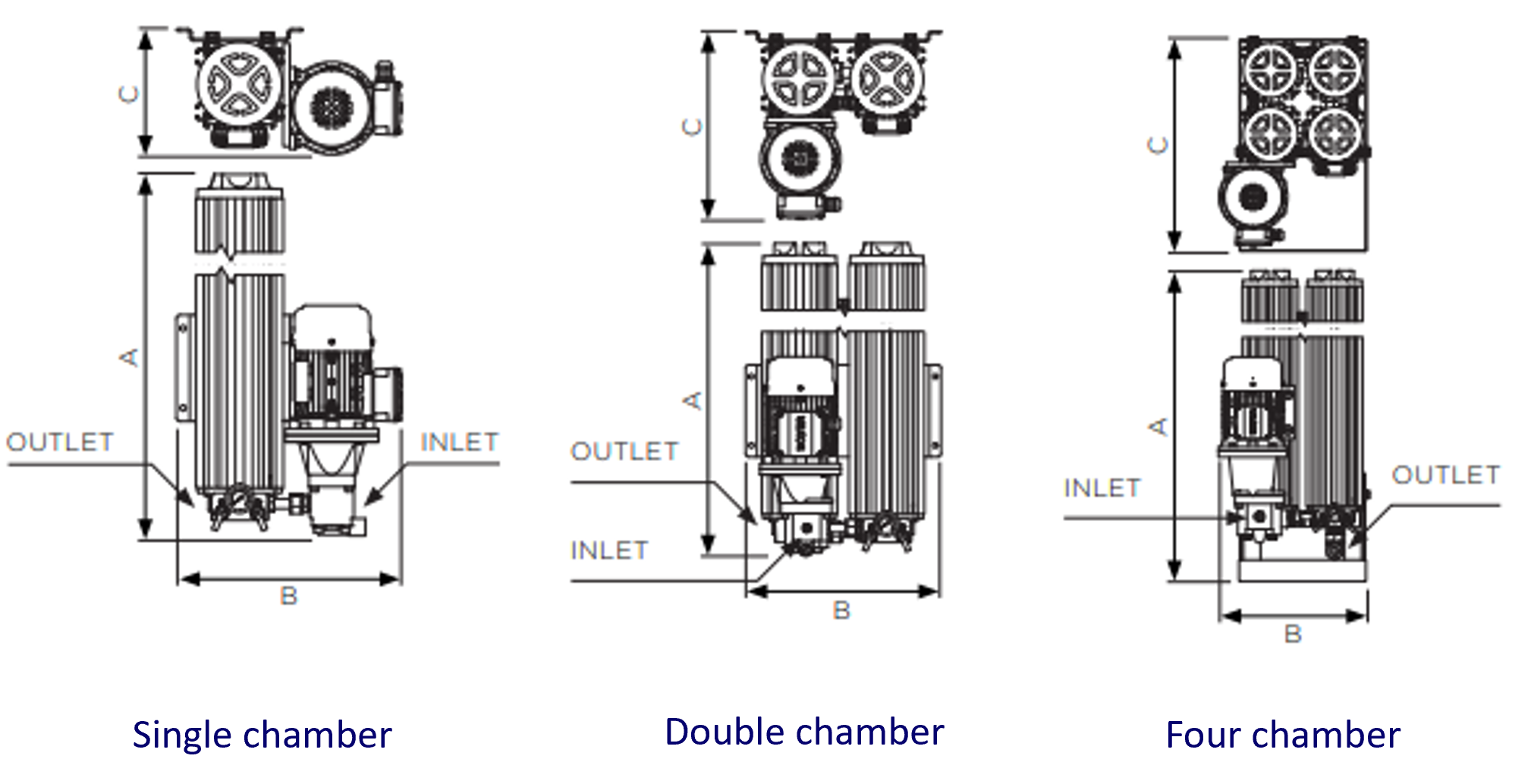

The off-line filtration units (OLU) provide best-in-class low-flow filtration for a majority of industrial applications.

Features:

- Multiple power supply configurations

- Designed for continuous duty and 24/7 operation

- Modular design suitable for reservoir volumes up to 2,900 gallons (11000 liters)

- Fits various filter types and different micron ratings without any modifications

- Optional add-ons for on/off control, indicators & drip trays

- Available in various flow rates for perfect fit on every application

Performance:

- Nominal Flow Rate – 0.5 gpm up to 4 gpm

- Oil Temperature Range up to 176°F (80°C)

- Viscosity Range 59 – 2316 SSU (10 – 500 cSt) – Filter element dependent

- Filter Media – Depth, glass fiber and water absorbing

- Max. Working Pressure – 218 psi (15 bar)

- By-Pass Openings Pressure – 90psi (6.2 bar)

- Max. Recommended Reservoir Volume – 360 gal – 2.900 gal

- Fluid Compatibility – Hydraulic and synthetic fluids according to DIN 51524, 51525.

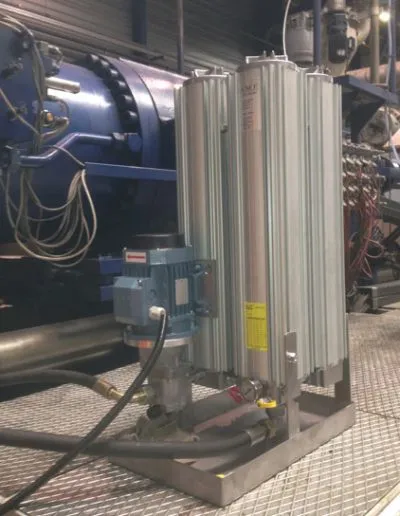

Giant Off-Line Unit

The Giant Off-Line Unit is also known as ‘The Giant’. The Giant’s filter housing is combined with a pump motor group and an electrical control box. This is an easy to use plug-and-play filter solution. It only requires electrical power, suction and return lines. The unit can be easily mounted to new and existing hydraulic installations. By means of an integrated pump-motor unit in the off-line filter, the oil is pumped from the reservoir through the filter unit and after filtering the oil is then returned to the tank. If required, elements are available in different micron sizes to suit any application. Water absorbing elements can also be applied.

Applications

The Giant can be used on hydraulic power units, lube and oil tanks, large gearboxes and storage tanks for biodegradable fluids.

Industries that are successfully applying ‘The Giant’ include: steel industry, marine industry, automotive industry, pulp & paper industry.

TC Series T-Stand

The TC Series T-Stands represent the highest quality and most rugged system available for dedicated filtration of all types of industrial oils. These heavy-duty systems are capable of removing particles and/or free water from all types of oil—even high viscosity gear oils—and are designed for years of dependable service.

TC Series T-Stands are ideal for large reservoirs with high flow rates. With canisters that can accommodate multiple filter types such as micro fiberglass drop-in filters, depth filters and bag filters, the TC Series T-Stands can remove everything from large particles and debris, sludge, varnish, and water contamination.

Applications

- Decontaminating systems

- Flushing new or repaired systems

- Pre-filtering new oil

- Collecting oil samples for analysis

Intended Use

- To be used for offline, secondary filtration and not inline filtration.

- In general industrial environments, both indoors and outdoors.

- For filtering mineral-based industrial oils and most synthetic oils with a maximum operating viscosity range of 32-648cSt (150-3000ssu) within ambient temperature ranges of -25°F to 104°F (-32°C to 40°C).

- Placed at the same level or below the equipment being filtered and with no more than 12-foot of adequately sized pipe/ hose

- This system should be stored and used on a level surface, right side up, in a low-traffic area, and connected to the appropriate power source.

Viscosity Range

- Up to ISO Vg- 680 (4,000 sus @ 100°F )

A T-stand is usually the best choice for improving equipment reliability. This is a permanently installed and always-on filtration system that cleans the oil and then keeps the oil clean. The T Stand can be permanently mounted, where it can serve as a maintenance station for continuous-duty for critical applications in difficult to access equipment.

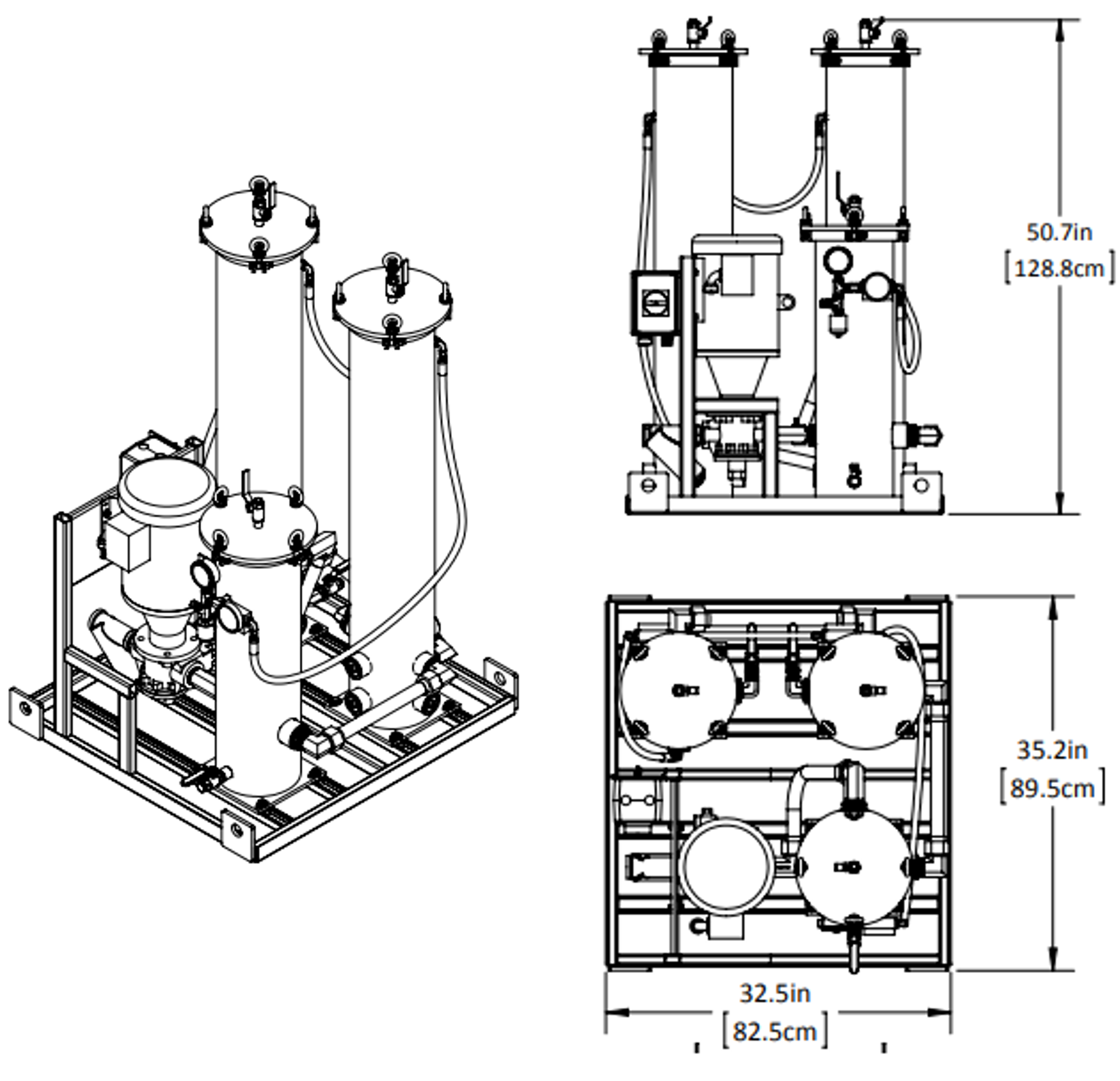

Three Canister TC Stand

An example of the three canister system of the TC Stand (see schematic configuration)

Materials:

- Frame: Heavy-duty rectangular tubing

- Lifting Eye Bolts: Allows for easy lifting and maneuverability

- Paint: Industrial powder coat

- Fittings: Zinc-plated steel, brass, bronze, stainless steel, cast iron

- Pumps: Steel, Buna-N, iron, Viton® , graphite

- Hoses: EPDM or nitrile

Product Features

Canisters: Heavy-duty, industrial style with bolt-down lids and heavy gauge cylinder walls. These canisters can accept various size high-capacity microfiber glass, depth, water removal and molecular sieve elements and can be changed very easily.

Pump: Continuous-duty gear pump; 1-40gpm flow rates available

Motor: Washdown, heavy duty

Switch: NEMA 4 industrial-duty Viscosity Range: Up to ISO VG 680 (4000sus at 100°F)

Mobile Off-Line Kit

The Mobile Equipment Engine Kits work by taking small amounts of oil after the OEM full flow filter and directing it through the engine kit. Oil flows through the canisters at a set rate and is returned directly to the engine sump. A pressure relief valve is also installed in the canister and returns to the reservoir to prevent accidental over pressuring of the canister during cold cranking.

The system is designed to prevent the canisters from being emptied when the equipment is shut down, while the small amount of oil directed through the engine kit at any given time ensures the engine is never starved of oil.

Where It’s Used:

- Loader hydraulic systems

- Dozer hydraulic systems

- Haul truck hydraulic systems

- Off-road mobile hydraulic systems and transmissions

Selecting the Appropriate Model:

- Up to 150 gallons of oil: HYD-1

- 151 or more gallons: HYD-2

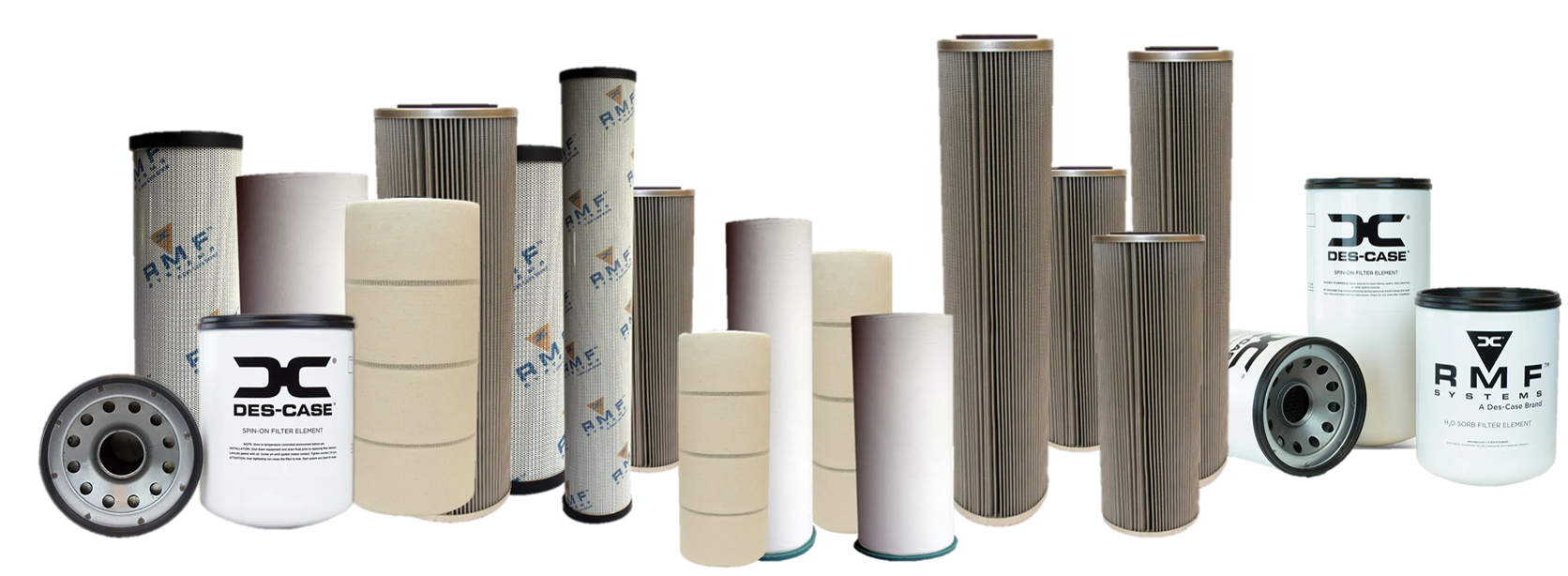

Filter Elements

Acufilt offers an array of filter elements to tackle water, particulate, varnish, sludge and acid removal in a wide variety of industrial applications. For each filter unit we have the right replacement element in the applicable efficiency (β-rating). Our spin-on elements have a large dirt and water retention capacity are also available in different micron ratings.