Its All About Keeping Your Investment Running

For your equipment to function as intended and avoid unplanned malfunctions and failures, planned maintenance is necessary. Regularly used equipment needs regular maintenance, and it can be safeguarded with preventive measures.

Here you will find information about products that ensure that hydraulic oil can be kept constantly clean, even in working machines. Our products effectively retain moisture and dirt, keeping the oil clean for longer period and keeping machines in optimal condition.

See Why Your Choice Matters To Do Business With Us!

Achieve Your Goals With Purpose & Strategy.

It’s Time For You To Think About Hydraulic Filtration!

Why hydraulic filtration?

First of all, you want your machine to operate worry free and without interruption. Actively filtering lubricants to acceptable cleanliness levels can dramatically improve equipment performance and lubricant life, preventing production downtime and high machinery repair costs.

Consider these long term savings when you apply hydraulic filtration for your equipment.

- Longer hydraulic oil service life means less frequent oil changes

- Longer machine runtime due to cleaner oil

- Planned production targets are met with reliable machines

- Lower maintenance costs means long term savings in operational costs

- Happy and motivated employees operating reliable machines.

What is oil filtration?

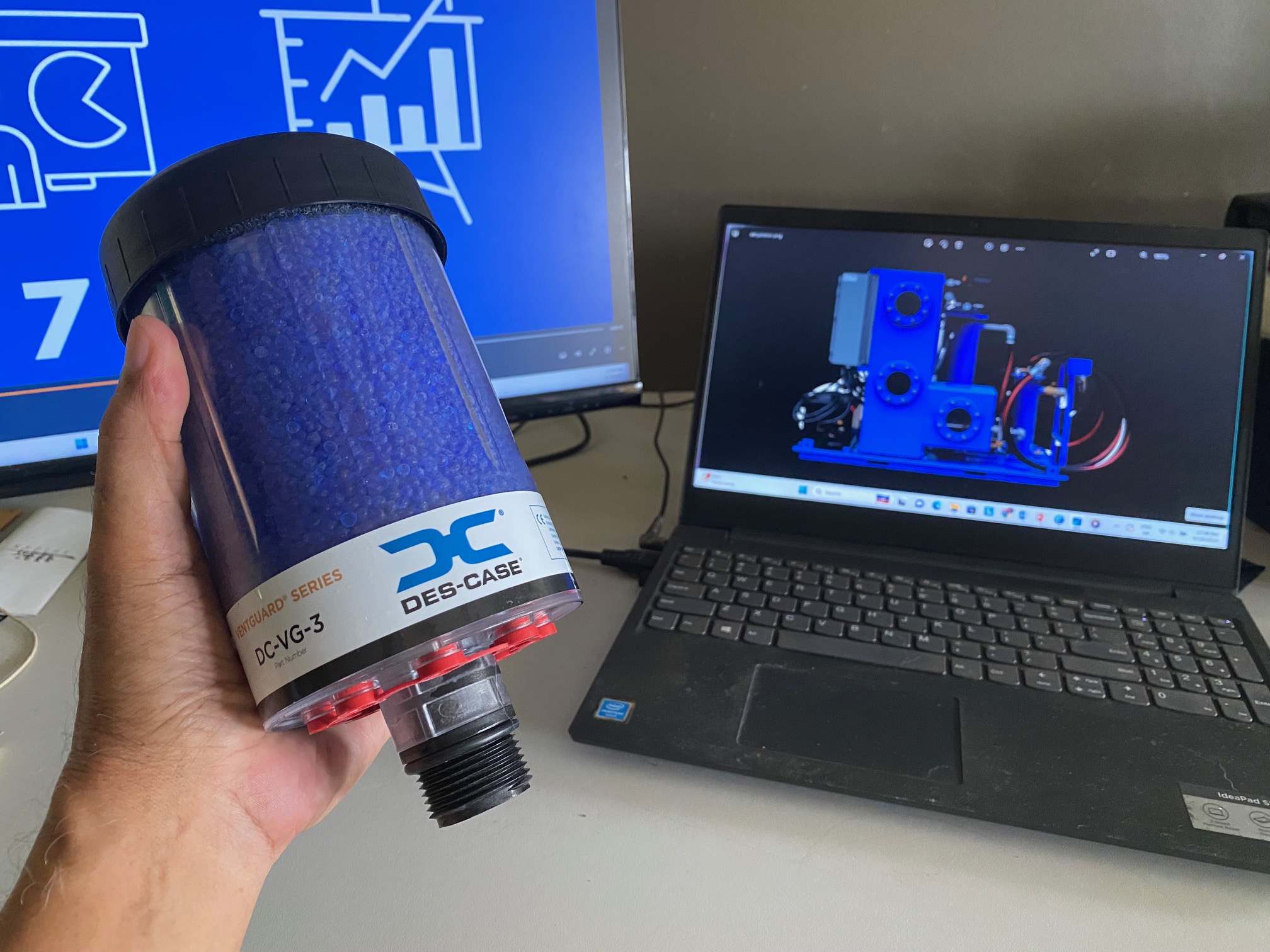

In hydraulic applications desiccant breathers and filter units play an important role. In most cases it is highly recommended to combine and utilize both to reach the best results.

Reservoir Filters

Breather caps and standard vents offer little to no protection. They don’t provide a way to collect moisture and are usually rated at 40 micron. Installing desiccant breathers in these ports will give continuous protection against water and dirt intrusions. Clean lubricants increase equipment longevity and reduce overall cost of ownership by reducing expenses associated with oil, repairs, downtime, and maintenance.

The health of lubricants and machinery depends on breathers. An essential first step in optimizing reliability is a desiccant breather that is fitted and maintained correctly. Utilizing breathers in conjunction with other methods of controlling contamination, like mechanical seals, appropriate sampling procedures, downstream filters, and suitable systems for storing and dispensing lubricant, will improve overall maintainability and raise the likelihood of reaching or surpassing life expectancy.

Basic forms of oil filtration

Oil filtering comes in two fundamental varieties: in-line and off-line. The pressurized supply line of any circulating system needs to have in-line filters on it to ensure that the oil given to the moving parts is dry and clean. Nevertheless, without major and expensive modifications, in-line filters sometimes fail to effectively manage pollutants at low enough levels.

In these situations, offline filtration is a great, economical option. By using an external pump to remove the oil from the main system, off-line filtration, sometimes referred to as by-pass or kidney loop filtration, allows for oil filtering even when the main system is not running. It is simple to change the filter elements and can be done without stopping the main system.